4 Components Every Diesel Engine Will Eventually Need Replaced

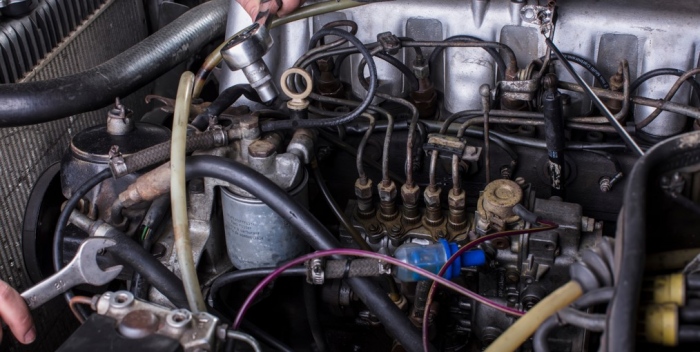

Diesel and gasoline engines are internal combustion engines, but the former has a compression-ignited injection system. Diesel fuel is ignited in the combustion chamber at high temperatures in a compression-ignited system. Like gasoline engines, diesel engine parts are subject to wear and tear, and the performance depends on the condition of the parts and how well it is maintained. Preventative maintenance involving the replacement of these four components is necessary to keep the engine in optimal working condition.

Rail Injector

The introduction of a common rail fuel injection system has revolutionized the performance and efficiency of diesel engines by providing a level of flexibility in emission control, power, and fuel consumption. The function of a common rail injector is to receive fuel from the pump and distribute it to the injectors under extremely high temperatures to increase fuel pressure. A common rail injection system is preferred for modern diesel engines because it maintains fuel pressure regardless of engine speed and load conditions and lowers fuel pump peak torque requirements. The diesel fuel injector has a short lifespan, usually around 100,000 miles, so you must replace it to avoid engine surge.

Diesel Fuel Filter

A diesel fuel filter protects fuel system components of the engine by removing foreign parts and water from fuel. A diesel fuel filter is usually designed to remove tiny particles to prevent failure of the engine. According to emissions analytics research, diesel engines emit less carbon dioxide and greenhouse gasses than gasoline engines, but diesel fuel is dirtier than gasoline, making fuel filters an essential component in a diesel application. A clogged fuel filter can damage your engine pump, hence, the need for regular replacement, usually after around 15,000 miles.

Pistons

Like gasoline engines, diesel engines have connecting rods, crankshafts, and pistons to transfer fuel energy from linear to rotary motion. The role of the piston in a diesel engine is to move up and down inside the engine cylinder while compressing the air and fuel mixture, then converting fuel energy into mechanical energy. The pistons might need replacement because of wear and tear, especially if the cylinders have too much taper wear and the block has to be bored to oversize. Piston replacement is necessary if the pin bore is worn more than 0.002 inches.

Air Filters

A clean diesel engine air filter optimizes fuel efficiency by allowing optimal airflow into the engine. With a clogged air filter, the engine might suck dirt and debris, causing damage to internal engine parts, such as cylinder walls, valves, and pistons. Replacing air filters minimizes oil consumption, maintains optimal engine performance, and prevents engine failure. Nonetheless, the frequency at which you should replace your air filters depends on the environment and the climatic conditions.

Most people prefer diesel engines because of durability, better fuel economy, and power, but the chances of breakdown are quite high without regular maintenance. Even though diesel engines lack spark plugs, regular servicing is necessary for optimal performance. In addition, replacing these important engine components reduces the chances of engine breakdown.